D2Shape product family involves digital printing systems that you can print directly on objects such as plastic bottles, buckets, containers, glasses, lids, and tin cans. These systems, which are based on printing with the Inkjet technique, are ideal solutions for the decoration of industrial objects made of diversified raw materials. “Direct” printing with Jetron D2Shape offers high print quality, and there are no quantity or color limitations. At the same time, it provides a low waste rate and eliminates the requirement for inventory holding. By reducing energy consumption and the use of chemicals, you can carry out eco-friendly production and achieve cost effectiveness.

CT40

CT80

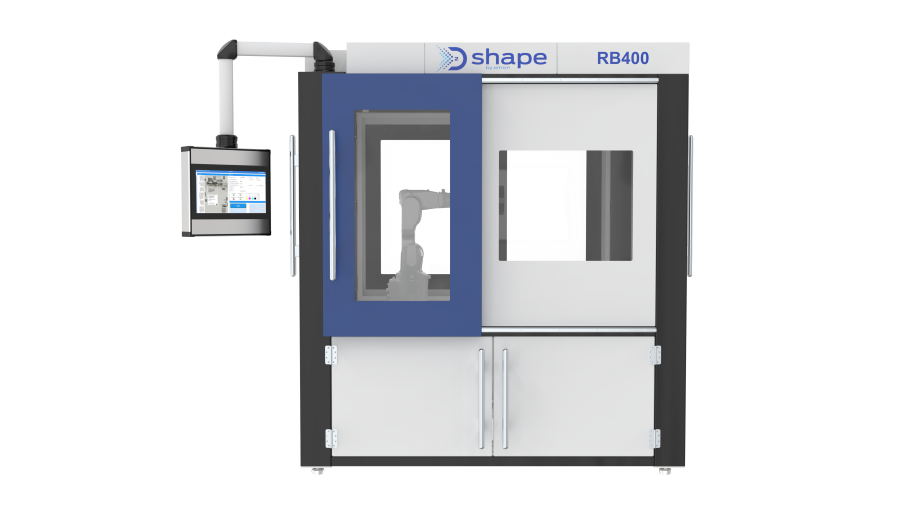

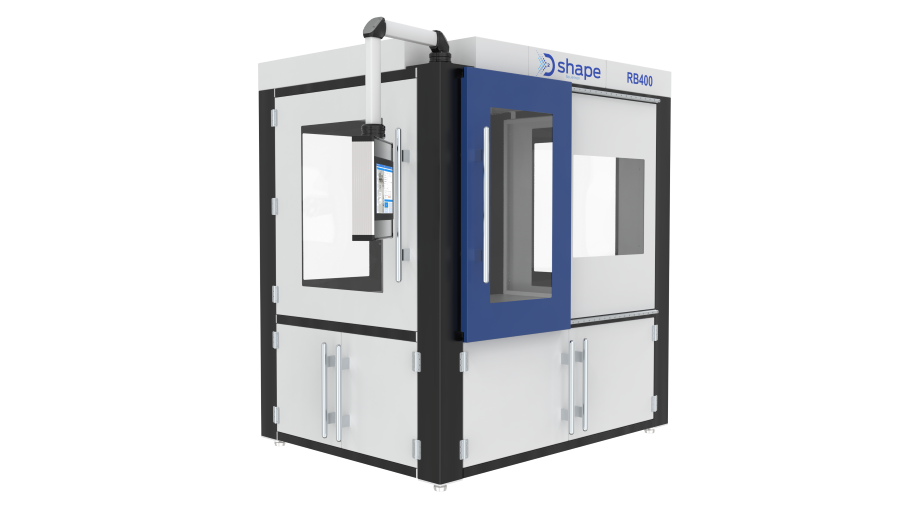

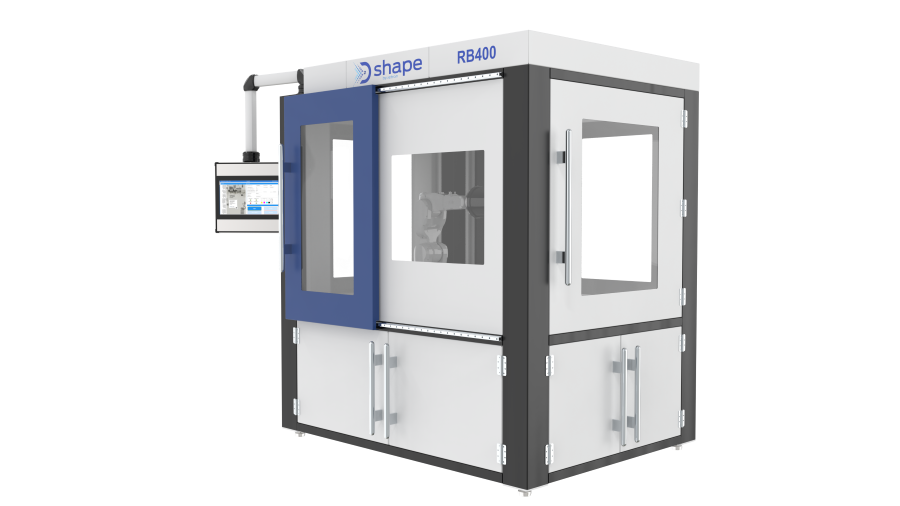

RB400

CC160